Our Injection Moulding Services Include:

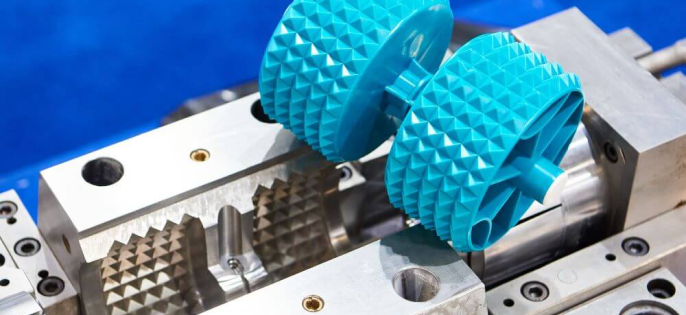

- Custom Mould Design: We work closely with you to design and develop custom moulds tailored to your product specifications. Our expertise ensures that the mould design optimally meets production needs while maximizing efficiency.

- High Precision Production: Utilizing state-of-the-art injection moulding machines, we produce parts with high precision and tight tolerances. Our equipment is capable of handling complex geometries while maintaining consistent quality throughout production runs.

- Material Selection: We offer a wide range of plastic materials for injection moulding, including ABS, polycarbonate, nylon, and more. You can choose the material that best suits your application, whether it calls for strength, flexibility, or specific aesthetic qualities.

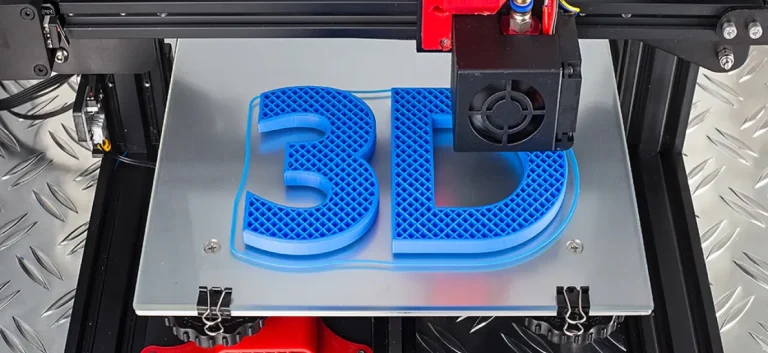

- Rapid Prototyping: Our injection moulding services can be integrated with rapid prototyping processes, allowing you to create initial production runs and test product functionality before committing to larger manufacturing volumes.

- Small to Large Production Runs: We are equipped to handle both small and large production runs, making us a flexible partner for projects of any scale. Whether you need a few hundred parts or thousands, we can accommodate your production needs.

- Quality Assurance: Each part produced undergoes rigorous quality checks to ensure that it meets industry standards and your specifications. This commitment to quality guarantees that your products are reliable and ready for the market.

With Fabin.uk’s injection moulding services, you can rely on us for efficient production solutions that bring your ideas to life. Our focus on quality, innovation, and customer satisfaction sets us apart in the industry. Contact us today to discuss your injection moulding needs and how we can support your project!