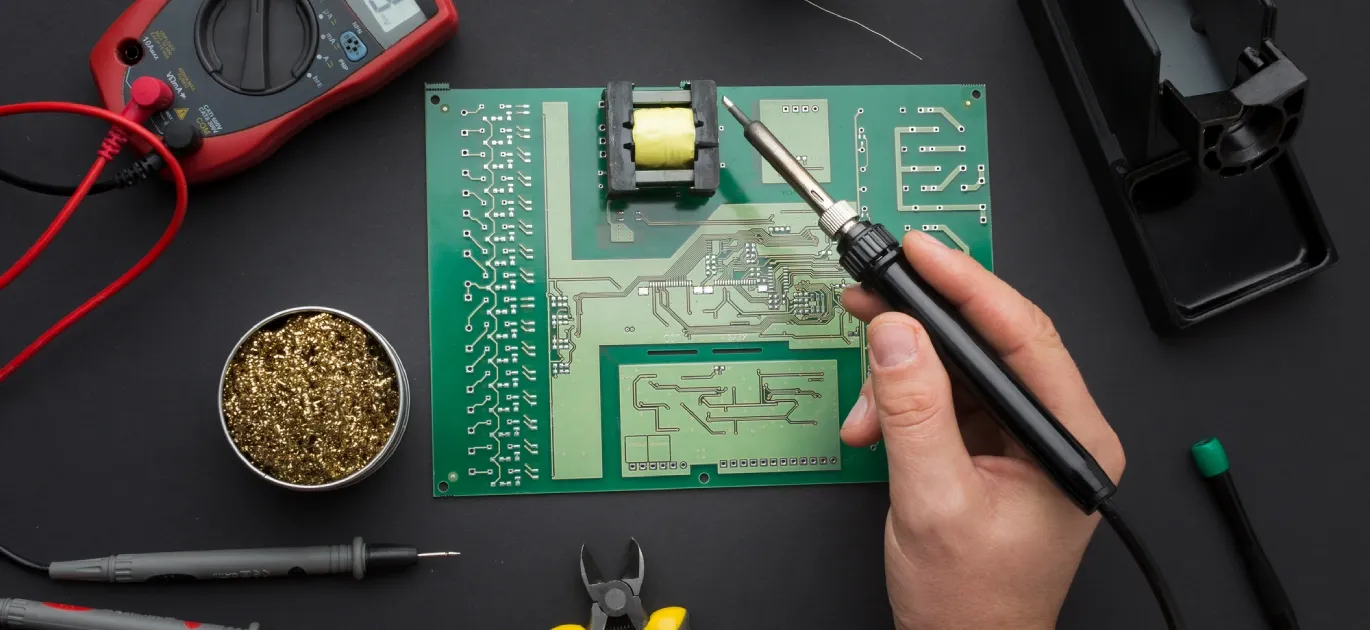

Our AOI Inspection Services Include:

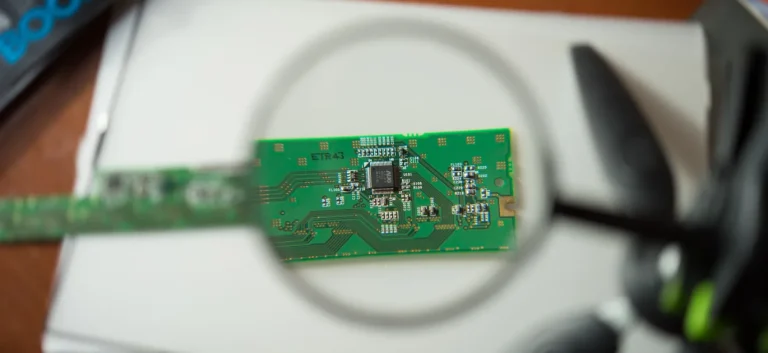

- High-Precision Imaging: Our state-of-the-art AOI systems capture detailed images of the PCB surface to identify potential defects, such as component misalignment, solder joint issues, and other irregularities that may affect performance.

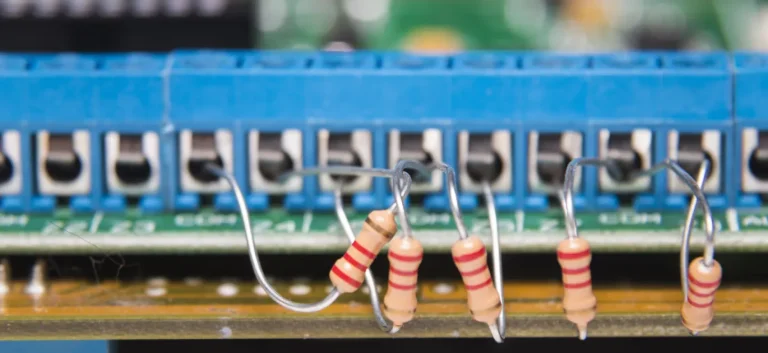

- Comprehensive Defect Detection: We check for a wide range of potential issues, including missing components, incorrect placements, insufficient solder, and more. This thorough examination helps prevent costly errors and ensures product reliability.

- Fast and Efficient: AOI inspection allows for quick evaluation of assemblies, providing immediate feedback and enabling rapid corrective actions. This efficiency helps to streamline the production process and minimize delays.

- Data Analysis and Reporting: Our AOI systems provide detailed reports on inspection results, enabling you to track quality metrics and identify trends over time. This data-driven approach ensures continuous improvement in your manufacturing process.

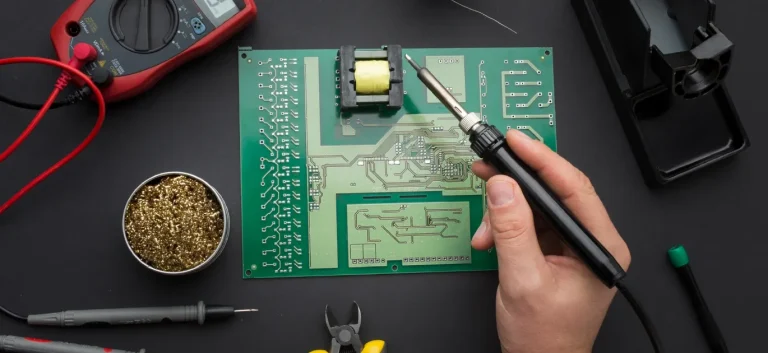

- Integration with Production: AOI inspection can be seamlessly integrated into your assembly line, working alongside other manufacturing processes to maintain a consistent workflow and uphold high quality standards.

By incorporating AOI inspection into our PCB assembly services, Fabin.uk ensures that your products are meticulously examined for quality and performance. Trust our expertise to deliver reliable and high-quality electronics that meet your stringent requirements. Contact us today to learn more about how our AOI inspection services can enhance your production quality!